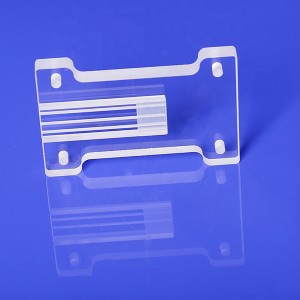

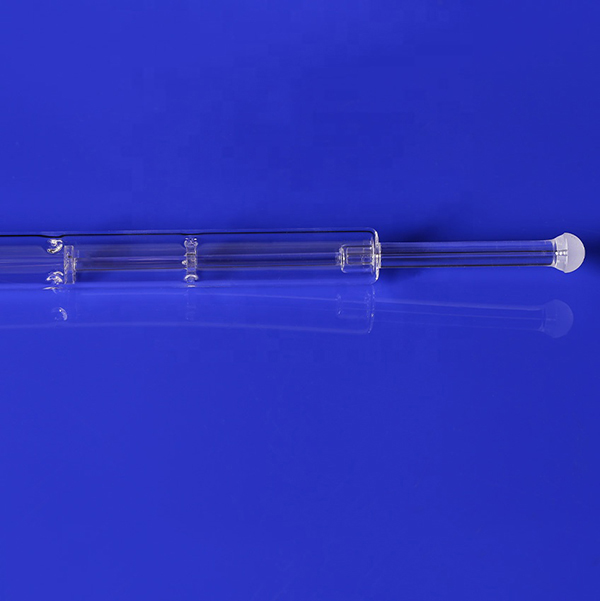

Fused quartz pob thiab pob qij txha

Quartz Machined pob pob qij txha yog siv rau cov cuab yeej xav tau cov pob qij txha nrog lub zog ntxiv, durability thiab qhov sib xws.

Customization ntawm lwm cov duab

Khoov

Beading

Doming

Tubulations

Xaus kaw

Vuam

Khoom zoo

Kub kub endurance

Tsawg coefficient ntawm thermal expansion

Zoo thermal shock tsis kam

Hluav taws xob rwb thaiv tsev zoo heev

Cov tshuaj purity siab

Kev ua haujlwm siab tshaj plaws ntawm 1100 ° C (mus tas li), lossis 1300 ° C (lub sijhawm luv)

Cov khoom qhia

Daim ntawv thov

Cov cuab yeej kuaj

Chemical apparatus

Chemistry thiab pharmaceutics

Quartz yam ntxwv

| Qhov ntom | 2.2g / cm3 |

| Tensile zog | 50 Mpa |

| Inflection kuj | 60-70 ib |

| Compressive zog | 80-1000 Nws |

| Kev cuam tshuam tsis kam | 1.08 Kg.cm/cm2 |

| Mohs hardness | 5.5-6.5 |

| Hluav taws xob kuj nyob rau hauv nirmal trmperature | 1018 (200C)Ω.cm |

| Dielectric tas li nyob rau hauv ib txwm kub (ε) | 3.7 (Hz 0 ~ 106) |

| Dielectric zog nyob rau hauv ib txwm kub | 250-400 kW/cm |

Lub Sijhawm Lead

Rau cov khoom seem, peb yuav xa tawm hauv ib lub lis piam. Rau cov khoom customized, thov hu rau peb kom paub ntau ntxiv. Yog tias koj xav tau ceev, peb yuav npaj ua ntej.

Sau koj cov lus ntawm no thiab xa tuaj rau peb