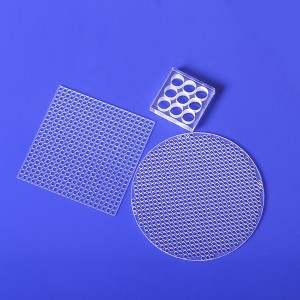

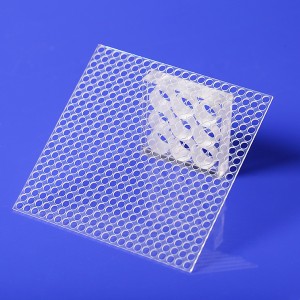

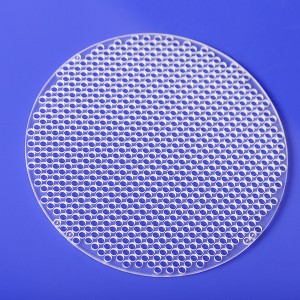

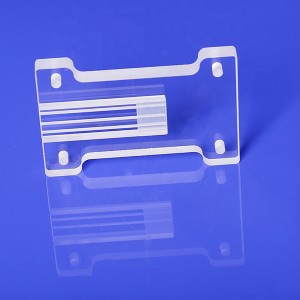

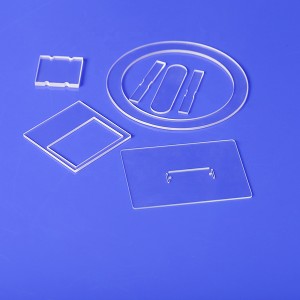

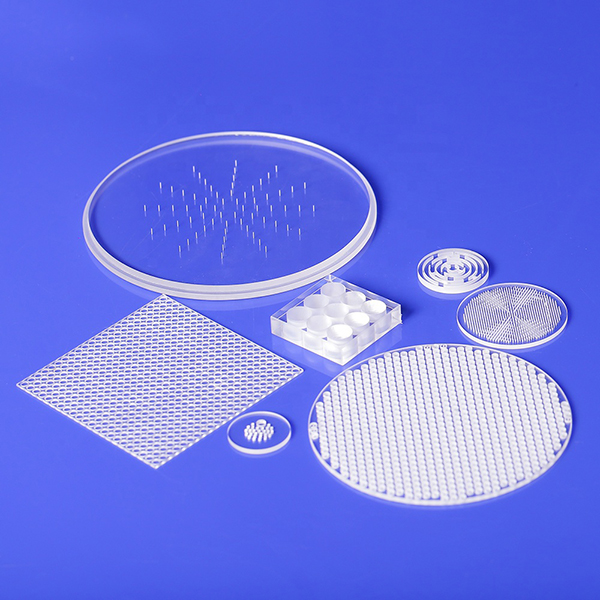

CNC Machining JGS1 Fused Silica phaj nrog lub qhov

Lub High Precision ntawm CNC Machined tuaj yeem muab cov khoom zoo quartz iav, xws li slotting, drilling, thiab beveling.Qhov zoo dua yog tias qhov kev ua haujlwm raug siab thiab nws tuaj yeem ua tau raws li qhov xav tau ntawm cov neeg siv khoom sib txawv.

1.Custom Design thiab Tailor-Made tau txais tos.

2. Ntau yam ntaub ntawv xws li Quartz, Fused Silica, Ntau Yam Kho Qhov Muag iav

3.The High-Precision Fabricated Parts xa Superior Quality thiab Long Lifespan.

Tuam Tshoj Optical Quartz iav Qib

| Lub npe | Cov qib sib thooj | Feature |

| Far Ultraviolet Optical Quartz iav | JGS1 | Pob tshab hauv ultraviolet thiab pom spectrum;tsis muaj kev nqus band hauv 185-250nm band;muaj zog nqus band hauv 2600-2800nm band;non-luminous, ruaj khov lub teeb hluav taws xob. |

| UV optical quartz iav | JGS 2 | Pob tshab hauv ultraviolet thiab pom spectrum;tsis muaj kev nqus band hauv 200-250nm band;muaj zog nqus band hauv 2600-2800nm band;non-luminous, ruaj khov lub teeb hluav taws xob |

| Infrared optical quartz iav | JGS3 | Pob tshab hauv qhov pom thiab infrared spectrum;tsis pom tseeb nqus band hauv 2600-2800nm band; |

Khoom siv

UV Fused silica

Schott borofloat 33 iav

Sapphire

Tempered iav

Specification

Peb tuaj yeem ua ntau yam quartz qhov chaw raws li daim duab kos.Yuav luag txhua qhov quartz yog ua los ntawm CNC machining, me me yog pab los ntawm cov khoom siv laser.Peb ua haujlwm thiab muab ntau lub peev xwm hauv kev ua cov khoom siv iav.

CNC milling chaw nrog lub rooj loj tshaj plaws yog 24 "x 36"

CADCAM Dej dav hlau milling chaw nrog lub rooj siab tshaj plaws ntawm 26 "x 52"

Cov khoom qhia

Daim ntawv thov

Printing thiab dyeing

Qhov rai kho qhov muag

Kub tiv thaiv daim hlau

Pedestals rau cov tshuaj tiv thaiv chav

Quartz npog daim hlau

Kub resistant accessories ntawm semiconductor khoom

Lub tshuab nqus tsev txheej khoom siv

Quartz yam ntxwv

| SIB 2 | 99.99% |

| Coefficient ntawm Expansion | 5.54 x 10-7 (K-1) |

| Strain Point Kub | 1343 Degree K |

| Softening Point | 1933 Degree K |

| Thermal conductivity | 1.37 W / m 0K |

| Annealing Point Kub | 1 4330k |

| Qhov nruab nrab kub tshwj xeeb - | 771 KWG |

| Optimal Ua Haujlwm Kub | 1423-1473 0 K |

| Tshwj xeeb kub conductivity | 1.48 W/mK |

| Acid kam rau ua | 30 npaug tshaj ceramic, 150 npaug tshaj stainless |

| Qhov ntom | 2.204 g / cm3 |

| Tensile zog | 49 N / mm2 |

| Poisson's Ratio (No Unit) | 0.17 ib |

Yog tias koj tab tom nrhiav Machined quartz discs thiab Machined quartz phaj lwm tus neeg uas tuaj yeem xa cov khoom lag luam customized thiab zoo Machined quartz daim hlau, tiv taujTeb Chaws Asmeskas.